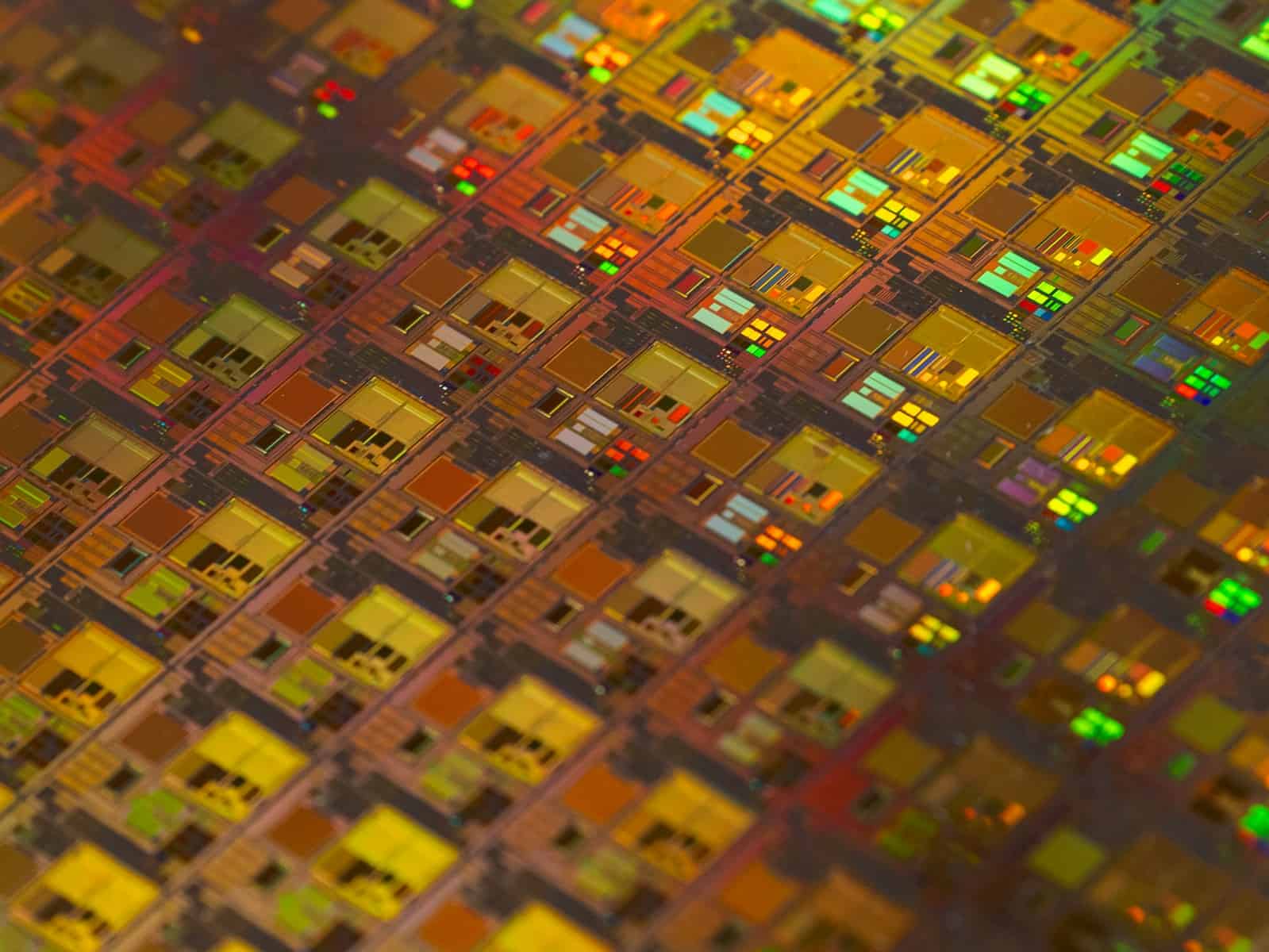

Semiconductor manufacturing is crucial for modern technology. These small chips power many things, such as smartphones and cars. Without them, a lot of the devices we use every day wouldn’t work. Making semiconductors involves several steps. First, raw materials are prepared. Then, they go through stages like etching and photolithography to create the circuits. Each small chip is an important part of what makes our gadgets work. Understanding how these chips are made can help people appreciate the technology they use every day. Knowing the basics of semiconductor manufacturing gives insight into why these small components are so powerful and essential to our lives.

Semiconductor Fabrication: A Deep Dive into the Process

Semiconductor manufacturing, or fabrication, is a complex multi-step process that involves transforming raw materials like silicon into the integrated circuits (ICs) that power modern electronics. The process is carried out in specialized facilities known as fabrication plants, or fabs. Semiconductor manufacturing is a meticulous and complex process. It underpins the creation of the integrated circuits (ICs) that power everything from smartphones to supercomputers. From the purification of raw silicon to the intricate wafer processing and final packaging, each step is crucial in producing the high-performance chips that drive innovation across industries. This article delves into the intricacies of semiconductor fabrication, exploring the challenges and emerging trends that shape this critical field.

Raw Material Preparation (H4)

The journey begins with the purification of silicon, a naturally abundant element found in sand. This purification process yields electronic-grade silicon (EGS), which is then melted and grown into cylindrical ingots. These ingots are subsequently sliced into thin wafers, typically 300mm in diameter, forming the substrate for the ICs.

Wafer Processing (H4)

Wafer processing is the heart of semiconductor fabrication. This stage involves a series of intricate steps, including:

- Oxidation: A thin layer of silicon dioxide is grown on the wafer surface to act as an insulator and protect the underlying silicon.

- Photolithography: This process uses light to transfer a circuit pattern from a photomask onto the wafer. The areas exposed to light become soluble, while the unexposed areas remain insoluble.

- Etching: The soluble areas are removed by chemical or plasma etching, leaving behind the desired circuit pattern.

- Deposition: Thin films of various materials are deposited onto the wafer to form conductors, insulators, or semiconductors.

- Ion Implantation: Dopant atoms are implanted into the wafer to modify its electrical properties, creating the transistors that are the building blocks of ICs.

- Metallization: A layer of metal, usually aluminum or copper, is deposited and patterned to interconnect the various components on the chip.

Wafer Test and Packaging (H4)

After processing, the wafers undergo rigorous testing to identify and discard defective chips. The good chips are then separated and packaged into individual units, ready for assembly into electronic devices.

Key Challenges and Trends (H3)

Semiconductor manufacturing faces several challenges, including:

- High Cost: Fabs are incredibly expensive to build and operate, with costs often exceeding billions of dollars.

- Complexity: The fabrication process is highly complex, involving hundreds of steps and precise control of materials and processes.

- Yield: Not all chips produced on a wafer will be functional. The yield, or percentage of good chips, is a critical factor in determining profitability.

- Miniaturization: The demand for smaller, faster, and more power-efficient chips drives the need for continuous miniaturization, which poses significant technical challenges.

- Environmental Impact: Semiconductor manufacturing consumes large amounts of energy and water and generates hazardous waste.

Despite these challenges, the semiconductor industry continues to innovate, driven by the insatiable demand for electronic devices. Emerging trends include:

- 3D Integration: Stacking chips vertically to increase density and performance while reducing size and power consumption.

- New Materials: Exploring new materials like gallium nitride and silicon carbide to improve the performance and efficiency of power electronics.

- Advanced Packaging: Developing new packaging technologies to protect and interconnect chips, improve thermal management, and enable new functionalities.

- Sustainable Manufacturing: Implementing greener practices to reduce the environmental footprint of semiconductor fabrication.

| Process Step | Description |

|---|---|

| Raw Material Preparation | Purification of silicon, growth of ingots, slicing into wafers. |

| Wafer Processing | Oxidation, photolithography, etching, deposition, ion implantation, metallization. |

| Wafer Test and Packaging | Electrical testing of wafers, dicing into individual chips, packaging of good chips. |

| Key Challenges | High cost, complexity, yield, miniaturization, environmental impact. |

| Emerging Trends | 3D integration, new materials, advanced packaging, sustainable manufacturing. |

Key Takeaways

- Semiconductors are key to modern technology.

- The manufacturing process involves multiple steps.

- Understanding their creation helps appreciate their role.

Fundamentals of Semiconductor Manufacturing

Modern semiconductors are crucial to many devices. Making these components involves precise materials and processes, continual innovation, and complex integration.

Materials and Processes

Silicon is the primary material used in semiconductors. It is extracted from silica and purified. The first step in manufacturing is wafer fabrication. Here, silicon crystals are grown, sliced into thin wafers, and polished.

The next steps include doping, which adds impurities to improve conductivity, and etching, where unwanted material is removed. Deposition layers the wafer with various materials, and photolithography uses light to create detailed patterns. These steps are repeated to build transistors and circuits.

Patterns of Innovation and Investment

Semiconductor manufacturing relies on constant innovation. Companies like Intel, NVIDIA, and TSMC invest heavily in research and development. Advances in artificial intelligence and machine learning drive new designs and processes.

Investment in new manufacturing plants is critical. These facilities are expensive and require advanced technology. Governments and private sectors often work together to fund these projects. This collaboration ensures continuous improvement and competitiveness in the global market.

Integration in Modern Devices

Semiconductors power many modern devices. They are found in smartphones, laptops, vehicles, and medical equipment. Integrated circuits are the building blocks of microchips used in these devices.

Companies such as Apple, Samsung, and Qualcomm rely on advanced semiconductors for their products. These chips help devices run more efficiently and handle complex tasks. In electric vehicles, semiconductors manage power distribution and improve battery life. In consumer electronics, they enhance performance and functionality.

Maintaining high-quality standards in semiconductor manufacturing is vital. It ensures reliability and performance in all these advanced applications.

Frequently Asked Questions

Semiconductor manufacturing has deeply impacted modern technology, transforming electronics and daily life. Here, common questions about its influence and importance are addressed.

How has semiconductor manufacturing influenced the development of modern technology?

Semiconductor manufacturing has allowed for smaller, faster, and more efficient devices. Smartphones, computers, and advanced medical equipment all rely on semiconductors. These tiny components have driven innovation in nearly every tech field.

What are the implications of semiconductor technology in everyday life?

Semiconductors power everyday gadgets like phones, computers, TVs, and even kitchen appliances. They enable constant connectivity and smart technology features that people have come to rely on daily.

In what ways have semiconductors transformed the electronics industry?

Semiconductors have revolutionized the electronics industry by making devices more efficient and powerful. They have enabled the creation of more compact and portable devices, changing how people interact with technology and making electronic devices more accessible.

What is the significance of semiconductor physics to technological advancement?

Understanding semiconductor physics is crucial for enhancing device performance. It helps engineers design better transistors and integrated circuits, which are the building blocks of modern electronics. This knowledge leads to improvements in speed, efficiency, and power consumption.

How do semiconductors contribute to the overall growth of the tech industry?

Semiconductors are essential for the continuous growth of the tech industry. They are used in almost all modern devices, driving innovation and the development of new technologies. This contributes to the growth of industries such as computing, telecommunications, and entertainment.

What distinguishes semiconductors from conductors in electronic applications?

Semiconductors can control electrical current flow, unlike conductors which allow it to flow freely. This unique property makes semiconductors ideal for creating transistors and integrated circuits, which are essential in electronic devices for processing and storing information locally.